how to draw a 3d horse step by step

Thank you to 3D printing, we can print brilliant and useful products, from homes to hymeneals accessories. 3D printing has evolved over fourth dimension and revolutionized many businesses along the way.

This relatively new technology has disrupted the medicine, music, way and automotive industries — for the better. Accept a look at some impressive real-world examples of 3D printing and the companies that take embraced this advanced technology.

Motorbike

Are nosotros living in the year 3000? The Berlin-based engineering science company BigRep definitely makes it look like we're already in the futurity. This company is ready to change the motorcycle industry. BigRep developed the globe'due south starting time 3D-printed motorcycle called NERA (and it looks amazing).

The 3D-printed e-motorbike is fully made from scratch, from the tires to the frame. The only components that weren't printed were the electronics. Fifty-fifty improve, BigRep plans to let its users print replacement motorcycle parts from home instead of ownership pieces in stores.

What's life similar under the bounding main? Humans may exist able to know the answer sooner than we idea. Art graduate Jun Kamei created an incredible 3D-printed garment with gills called Amphibio. The amphibious gill could allow humans to exhale underwater.

Kamei was inspired to create Amphibio to help humans survive if a alluvion occurs or if the earth becomes submerged due to ascension bounding main levels. Amphibio is a groundbreaking invention (whatever the aquatic future may hold). Are yous tempted to buy these gills?

Dresses

Mode and pattern have too embraced 3D technology. Many dresses have been created thank you to 3D printing, including wedding dresses and runway dresses. Printing a gown is cheaper, easier and quicker. At present, you don't need to shop for a clothes at the store anymore — you tin develop one correct at home!

In Shanghai, designers 3D printed intricate wedding dresses that took one week to make. These luxury gowns toll upward to $3,200. Dutch manner designer Iris van Herpen as well featured 3D-printed dresses at a track show. Her printed creations took the forms of a squid, an octopus and other ocean creatures.

Bridges

Bicyclists and pedestrians can at present cross on 3D-printed bridges. Some of these bridges have popped up effectually the world. In fact, the globe'southward commencement 3D-printed span is located in Gemert, kingdom of the netherlands. In Prc, Shanghai has one of the largest 3D-printed concrete bridges on the planet, measuring 86 feet long and 11 feet wide.

Dutch offset-upwards MX3D plans to install a 3D-printed stainless steel bridge. Using industrial robots to print the span, MX3D finished the project after four years. The bridge is expected to appear in Amsterdam'southward carmine light district over the Oudezijds Achterburgwal culvert.

Prosthetic Artillery

Traditional prostheses are expensive, but 3D printing has the potential to put an end to that problem. In one case, college students used a 3D printer to create a prosthetic arm for six-year-sometime Alex Pring. The new arm only cost $350 to brand, while many prosthetic artillery can cost upward to $forty,000 each.

Cheers to 3D-press enthusiasts, people like Pring can afford artificial body parts. In fact, a medical charity hospital in Hashemite kingdom of jordan produced 3D-printed prosthetics for victims of war. For those looking for superhero-inspired prosthetics, The Hero Arm develops strong, bionic 3D-printed prosthetic arms.

Homes

Homebuilding techniques are changing. Thanks to 3D printing, homes tin exist congenital in less than 24 hours at a cost of only $iv,000. Other than cheaper prices and faster construction periods, 3D press could likewise help those living in poverty.

In fact, a housing charity company has already teamed up with a tech construction company to tackle global homelessness, and people are living in these extraordinary homes. A family from France became the world's kickoff to live in a 3D-printed house. For those looking for luxury 3D-printed smart homes, haus.me sells homes that allow customers to live off-grid almost anywhere.

Guitars

If you love musical instruments, you can 3D impress them also. For instance, you tin create all types of guitars, from audio-visual to electric. Printing a guitar tin can be cheaper, faster and more convenient than purchasing one. Making traditional prototypes for instruments takes many hours of trial and error. All the same, a 3D printer tin reduce the time.

The quality is just as good as an instrument made of woods or metallic. British indie rock band Klaxons performed using a printed guitar. Also, the globe's starting time live concert with 3D-printed instruments took place in Sweden. The group printed a drum, keyboard and two guitars.

Weddings

Many couples try to notice tips and tricks for saving money on their weddings. Withal, one helpmate cut costs for her special twenty-four hour period using a 3D printer. Harnessing her love for 3D printing, Erin Winick designed and created her headband, the table numbers, the cake topper, the floral cake decorations and the blossom girl'south necklace using a 3D printer.

She also printed near 200 flowers for the bridesmaids' and helpmate'south bouquets. For more than 100 hours, Winick cranked out and put together all the bouquets. Some guests had no thought she 3D-printed her wedding ceremony and thought everything was store-bought.

BMW's Millionth Component

While 3D printing isn't new, some luxury brands back up information technology more others. Since 2010, BMW has adopted 3D-press processes to manufacture car components. The automotive company reached a huge achievement by printing ane 1000000 components over the form of a decade.

It all started 25 years agone when BMW began testing out the new engineering science. The company used 3D printing for prototypes and development at first. Eventually, information technology printed automotive components for mass production. Although the visitor has already reached a major accomplishment, BMW is just getting started with 3D printing.

Refabricator

NASA is one step closer to turning one person's trash into another person'due south treasure. The space bureau invented the "Refabricator," a system that takes 3D printing to a whole new level. The Refabricator lets astronauts recycle waste to create new tools while in orbit.

With the assistance of the Refabricator, astronauts can stay in space longer. Every bit of late 2019, the 3D printer remains 250 miles above us on the International Infinite Station. Perhaps people on Earth will be able to use this incredible technology to recycle all types of waste someday.

Wheelchair Ramps

With 3D printing, information technology's possible to create bright and useful products. For instance, German disability rights activist Raul Krauthausen designed a game-changing device. He invented a portable, 3D-printed wheelchair ramp. His prototype helps him ride upwards and down steps and curbs.

Krauthausen'south epitome took a lot of piece of work and optimization. The ramp had to be big enough to allow people in wheelchairs to move up or down average-sized steps but small-scale plenty to fit conveniently in a wheelchair's pocket. He besides shared his process online and so others can print mini wheelchair ramps for themselves.

Shoes

This technology is as well revolutionizing fashion footwear by creating custom-fabricated shoes for ameliorate support and fit. Large fitness brands have already released 3D-printed shoes for mainstream consumption. For case, New Residual began selling $400 3D-printed shoes in 2016. Adidas as well developed futuristic shoes in 2016, but the company just gave them to Olympics-winning athletes at beginning.

In 2018, Adidas kicked into full gear and dropped new tech shoes to the masses for a cost of $300 a pair. Of course, Nike welcomed the tendency also. The visitor released a 3D-printed, stretchy, water-expelling running shoe at a whopping $600.

Cars

Dreaming most driving a 3D-printed car? Well, information technology'south soon to become a dream come true. Thanks to 3D printing, the automotive industry is changing. For example, motorcar manufacturer Bentley created the Bentley Speed 6 using country-of-the-art metal 3D-printing technology.

The Blade is another instance of how the industry is evolving. Made for high performance, the Blade is set to be the world's first 3D-printed supercar. Strati plans to sell the world's first 3D-printed electric machine, which consists of far fewer parts than a traditional vehicle. And automotive companies aren't the just ones building cars. A father and son 3D-printed their ain "Lamborghini" in 2019.

Medical Models

3D-printed medical models are groundbreaking for preoperative analysis. The new engineering science allows healthcare professionals to print in dissimilar colors, textures, gradients and transparencies. Doctors and surgeons who study the models learn more about human anatomy due to the prints' realism and accurateness.

A Seattle doctor saved a spleen instead of removing it past utilizing 3D press. He practiced surgery on a printed spleen and acquired more cognition before performing the process on his patient. The exercise gave him confidence and helped cut the time of the surgery.

Makeup

Running low on makeup? Is your favorite lipstick discontinued? No problem. Whether it's lipstick or eyeshadow, it's possible to create cosmetics with 3D printing. One woman developed a portable makeup printer called Mink, allowing people to print at their homes, in their cars or even in their favorite coffee shops.

The co-founder of Mink, Grace Choi, says the colour options are endless. Thanks to Mink, users tin hands create makeup in any color using FDA-approved ink. For example, the device can print a pink eyeshadow in less than 40 seconds. Eventually, anyone can snap a picture of a friend's makeup and print it out later. What a fourth dimension to be live.

Coral

Coral reefs have besides merged with the 3D-printing revolution, and scientists believe 3D press may help the environment. For instance, using artificial corals could fix the damage that results from bleached corals. The 3D-printed versions of the invertebrates offering the possibility to save more than than just the coral, but also other organisms.

The artificial creations can also protect coral reef inhabitants. In fact, fish accept already embraced the 3D-printed coral as if it was the real thing. Researchers from Fiji used a coral skeleton and 50 iPhone images to develop effective and bonny 3D coral models.

Skin

Agree the phone. We can now impress peel cheers to 3D printers, although the technology is currently just tested on animals. Dr. James Yoo created a special 3D printer that can browse the wounds of fire victims and creepo out constructed peel right into the injuries.

Yoo successfully presented the ways the machine works on a hog. Now, the 3D skin printer is on standby for FDA approval to outset testing on humans. According to Yoo, the artificial skin heals burns and wounds faster also.

Furniture

Home decorations and engineering are merging more than ever before. Can't find the right dining chairs to become with the residuum of your home's décor? Instead of running to IKEA, consumers volition be able to customize their furniture with 3D printing.

UCL's Design Computation Lab is ane of the organizations that'southward paving the way for 3D-printed furniture. UCL developed a chair printed from plastic. Design brand Nagami too partnered with famous artists to develop 3D-printed chairs, and the collaboration was revealed during Milan Design Calendar week 2018.

Records

Vinyl LP records are returning to the mainstream, but some are coming back as 3D-printed versions. Using a 3D printer, music lovers can get close to the real matter. The sound on the new records is low-quality, but listeners can yet recognize the music.

According to Mashable, the earth'south kickoff 3D-printed record was unveiled during the 2013 SXSW festival. In that location are also 3D-printed tape players. Lenco-Doctor adult the starting time 3D-printed modular tape player in 2018, winning the best innovation award at a consumer electronics off-white.

Pet Legs

3D press can too change the lives of animals. A cute husky, Derby, was born without two front legs, and then his ability to motility was express. His possessor, Tara Anderson, provided him wheels for mobility, but these but weren't the right fit.

Next, Anderson made Derby 3D-printed prosthetics, and these were better tools for him. The prosthetics allowed him to run and sit only like other dogs. Thanks to 3D printing, more than dogs, cats and other pets have the take chances to walk and run in means they couldn't take before.

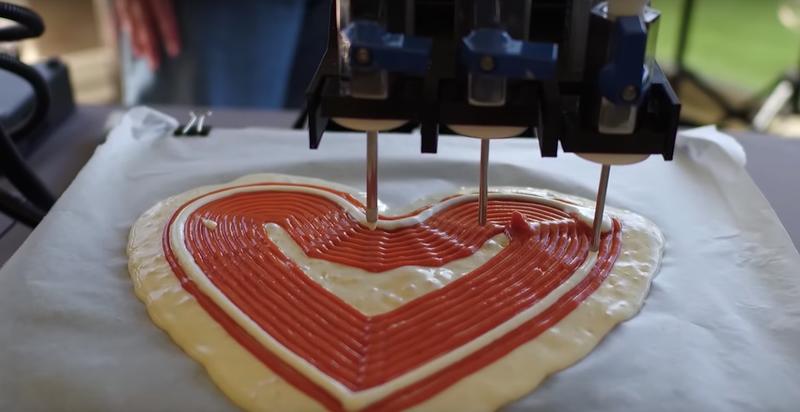

Food

3D-printed food may sound weird, simply information technology can even so be succulent. The ingredients are all real too. To 3D-impress food, the ingredients must be puréed and fit into a syringe-similar device in order to squirt onto a plate. Other ingredients must be added by hand.

There are many benefits of 3D printing food, such as bringing complex and artistic culinary visions to life. It tin can also assist astronauts in infinite to create meals and make meat more sustainable. People can 3D-impress all types of food, from pizza to spaghetti.

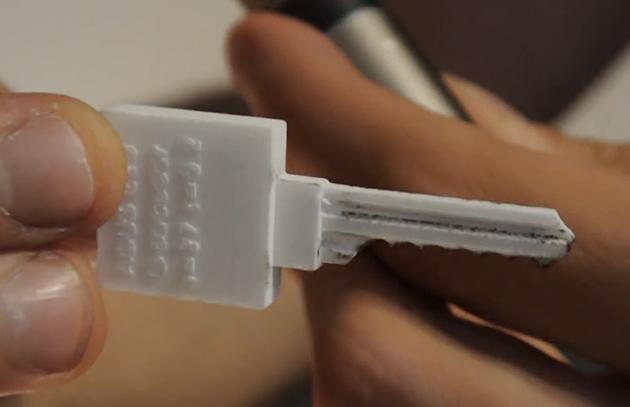

Keys

Locked out of the house or function? Forgot your keys? No worries. You lot can make a spare cardinal with a 3D printer and e'er accept a re-create with you. "Do not duplicate" keys aren't restricted, either. Thanks to Keysforge, you can replicate any key you want.

That's skilful news for people who forget or lose their keys oftentimes. Still, we besides have bad news: 3D-printed keys could exist a thief's ticket to unlocking whatsoever building. With merely a picture of a keyhole, researchers found a way to print out a working key using special software. Thankfully, the researchers aren't planning to sell their tech.

Organs

3D printing is going to brilliantly disrupt the medical industry. Believe it or not, we volition exist able to 3D-print solid organs eventually. Using the new technology, Organovo developed functional liver cells that survived for more than than 40 days. The production is currently merely for pharmaceutical testing.

However, researchers are one step closer to 3D-printed organs. Scientists at the Academy of Rochester Medical Center developed model organs that bleed, feel and look like real ones. Even meliorate, scientists at Harvard'due south Wyss Institute developed 3D-printed hearts with blood vessels and chirapsia heart tissue.

Camera

Can't afford the camera of your dreams? With the rise of 3D printing, photographers tin create custom cameras for themselves. London-based lensman Paul Kohlhaussen 3D printed many components to create his dream camera. Some people have likewise 3D printed entire cameras, including the lenses.

For instance, 3D modeler Amos Dudley designed and created a fully functional camera called SLO. SLO is a 35mm film camera with a "film cartridge, motion-picture show path, motion-picture show take-up spools, gears for rotating the spools, shutter, aperture plane, lens, film access door and a lightproof box."

Helmets

Need protective headgear? No trouble. 3D-print information technology! The Swiss Guards who protect the Pope at the Vatican always wear helmets, but for more than 500 years, those hard hats have been uncomfortable to article of clothing (especially in the hot sun). The guards no longer have to worry about the uncomfortable helmets.

Now, the guards happily put on 3D-printed helmets, which come with subconscious air vents and more space. The guards aren't the only ones who get to savour 3D-printed helmets, either. SpaceX developed a helmet that's almost entirely 3D-printed. The sleek headwear features air-cooling components and a retracting visor.

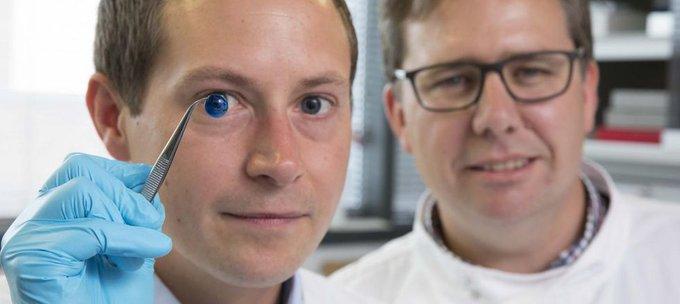

Corneas

Millions of people around the earth demand surgery for new corneas due to corneal blindness or scarring. Nevertheless, scientists may be one step closer to solving this problem cheers to 3D bioprinting. In early on 2019, University of Newcastle researchers developed a highly advanced "human" cornea using a 3D printer.

The report wasn't like shooting fish in a barrel. The researchers analyzed a volunteer's eye to create a model. They had trouble keeping the model'south rounded shape and getting ink that was the right consistency to fit in the printer's tube. Somewhen, the researchers successfully created an artificial cornea that's close to a real one.

Bikes

Arevo Inc. used 3D software and technology to create the globe's kickoff 3D-printed bicycle. The fully functional bike is made of carbon fiber. After two weeks, the company finished edifice the cycle. Although two weeks sounds like a long time, it'due south quicker than the traditional, more than labor-intensive process.

The Arevo bike looks and feels like a high-end wheel for commuting. The 3D-printed bike is too fully functional and stronger than titanium. Arevo doesn't program to produce or sell bikes for the masses, but the company wanted to show the incredible possibilities of 3D technology.

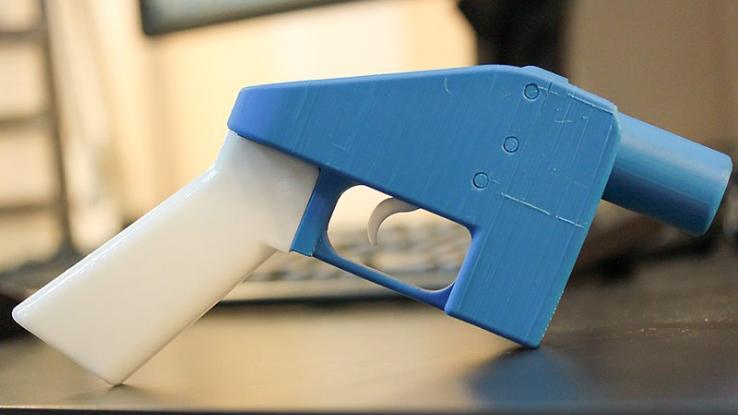

Weapons

Some of the most controversial creations of 3D printing are weapons, peculiarly guns. Defense force Distributed adult the offset 3D-printed firearm in 2013. Although 3D printers tin work with metals, information technology's expensive. Equally a result, Defence Distributed made the firearm from plastic.

Defense Distributed released a blueprint showing people how to build a 3D-printed firearm, and it was downloaded 100,000 times in two days. Concerned for public safety, multiple states filed lawsuits to stop the information'southward release. Consequently, a federal judge temporarily blocked the release of the pattern.

Basic

3D press has transformed the medical manufacture in many ways. One incredible example of how 3D printing has disrupted the industry is by fixing broken basic. After a bone breaks, plates and screws are oftentimes required to hold the damaged parts together as the bone heals.

Those days may shortly be over. Hala Zreiqat and her team at the Academy of Sydney adult a 3D-printed ceramic implant. The product successfully healed broken leg bones in rabbits. Even better, the products turned into the natural bone and repaired large leg fractures in sheep. Testing the production on humans may be next.

Glasses Frames

For those who vesture glasses, finding a frame that fits correct is challenging. The frames may be too big, also small or too uncomfortable. Fortunately, 3D printing is creating new and improved opportunities for customized glasses frames. Now, the eyewear industry has met the 3D press uprise.

Spectacles wearers are also happy about the boosted alternatives. Big brands similar GlassesUSA take adopted 3D press engineering science. Fitz Frames likewise allows users (both kids and adults) to create unbreakable 3D-printed spectacles through an app. Some people can also print their own frames at home.

Source: https://www.smarter.com/so-smart/real-world-examples-3d-printing?utm_content=params%3Ao%3D740011%26ad%3DdirN%26qo%3DserpIndex

0 Response to "how to draw a 3d horse step by step"

Mag-post ng isang Komento